Trenchless studies, design & monitoring

Site visits

Feasibility studies

Assisting project owners

Assisting works contractors

Calculations and modelling

Expertise and experience for all trenchless projects

With cutting-edge skills and a team of experienced engineers, many from drilling / tunnelling backgrounds, OPTIMUM delivers innovative solutions for the design and monitoring of trenchless crossings, big and small.

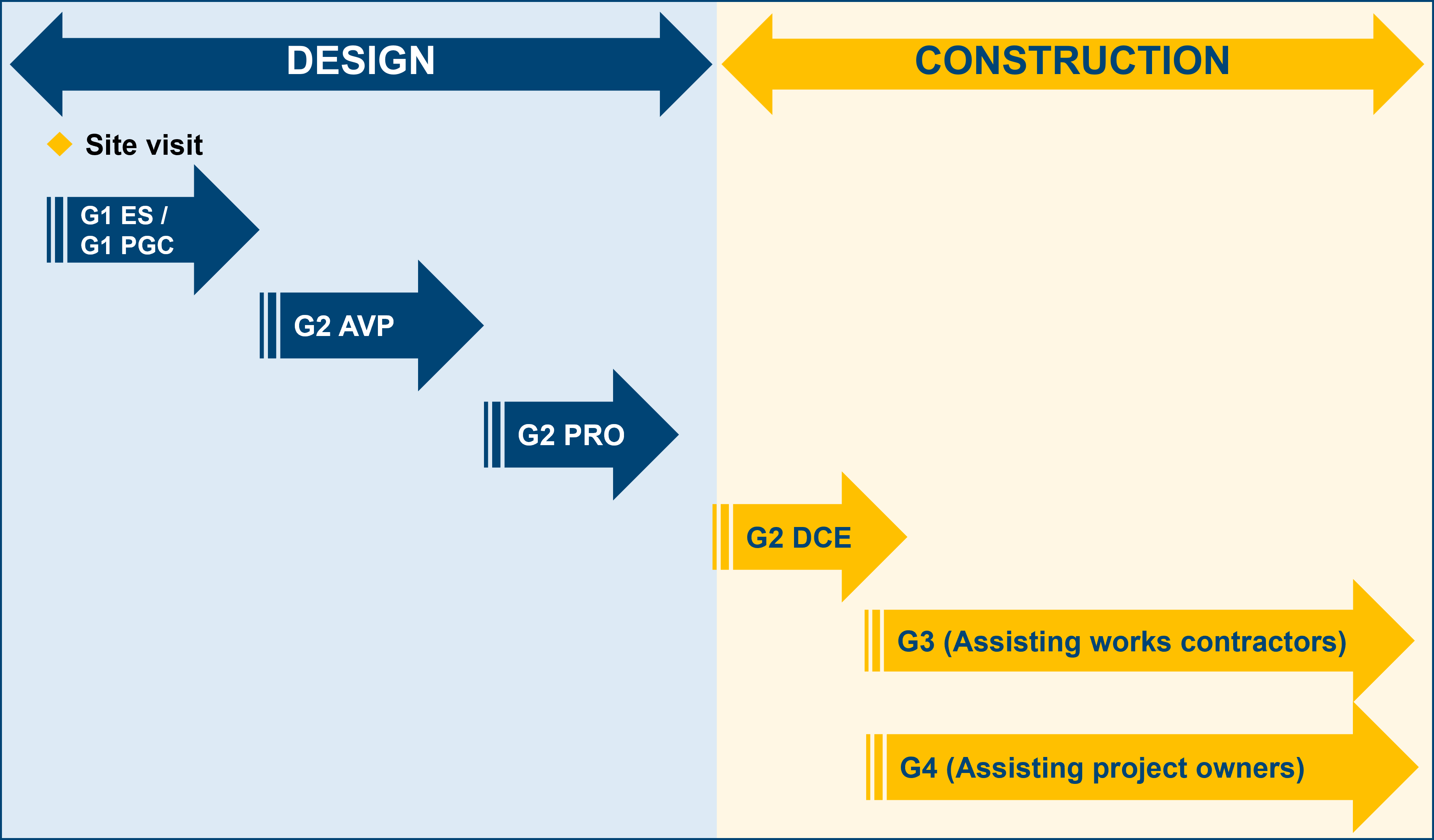

OPTIMUM’s specialist engineering teams accompany its customers at every stage of their trenchless project, from the initial design through to works completion: feasibility studies, selecting the most appropriate trenchless technique, designing the associated structures,

developing the purchase strategy, …

Site visits

A key stage in any trenchless project that allows for a better understanding of the context and constraints of the site.

Our site visit includes :

Discussions with the client on specific project constraints

Observation of the nature and elevation of the land

Identification of access roads, rights-of-way and potential job site locations

Identification of existing infrastructure (networks, obstacles, buildings).

Trenchless feasibility studies

An approach ensuring study accuracy and relevance

The success of trenchless crossings depends on several factors, with the quality and relevance of the pre-construction study being one the most critical.

When developing trenchless crossing studies, OPTIMUM applies a method based on the French NFP94-500 norm, which not only simplifies the development of the project, but also increases the efficiency and relevance of the ground investigations. Thanks to their jobsite

experience, OPTIMUM engineers have a perfect understanding of all trenchless techniques,

therefore optimising this crucial study phase.

Conceptual (G1 ES / PGC) study

A preliminary study aimed at establishing a geotechnical /geological model of the site with a view to preparing the detailed design phase of the project.

Our Conceptual (G1 ES / PGC) study includes:

Analysis of available bibliographic / geological data

Selection of the most suitable trenchless technique

Definition of the general construction guidelines

Development of a programme of geotechnical investigations and laboratory tests to be carried out before the FEED (G2 PRO) study

If required, budgets and planning schedules can also be estimated at this stage.

FEED (G2 PRO) study

A detailed feasibility study, drafted after receipt of the geotechnical investigations, which confirms or contests the hypotheses of the preliminary study.

Our FEED (G2 PRO) study includes:

Analysis of the results of geotechnical soil investigations

Definition of a soil model

Selection of the most appropriate trenchless technique

Definition of the technical parameters

Calculations and modelling

Sizing of the drilling / tunnelling equipment

Definition of the rights-of-way necessary for jobsite installation

Formulation of the preliminary modus operandi

Design of the crossing profile

Railway specific studies

A specific mission for crossings under SNCF railway tracks to precisely meet the strict design criteria.

Preparing a « TSV » dossier includes:

Drafting a dedicated risk analysis for the railway crossing

Verification of duct / pipe load resistance

Formulation of a protocol to ensure the integrity of the railway platform

Drafting a continuous, track alignment monitoring programme

Preparation of the complete dossier, in accordance with SNCF requirements

If required, OPTIMUM can also submit the dossier to the SNCF and handle negotiations until the necessary approvals have been received from SNCF Réseau.

Assisting project owners

G2 DCE / ACT Mission

A mission to support the Project Owner and / or Project Manager during the contractor selection phase: pre-selecting companies capable of carrying out the works and assessing the technical validity of their proposals.

Our G2 DCE / ACT mission includes:

Selection of contractors able to carry out the requested drilling / tunnelling works

Drafting the technical chapters of tender documents

Analysis of technical submissions

Evaluation of the technical eligibility of each bid

Attending the bidders’ technical presentations

Establishing a final technical scorecard

G4 Mission

A supervisory mission to support the Project Owner and / or Project Manager during the works preparation and construction.

Our G4 mission includes:

Supervision of the contractors’ plans and procedures before works begin

Supervision of the construction phase, including:

kick-off meeting

supervision and control of onsite operations

daily analysis of technical parameters

identification and monitoring of discrepancies until resolution

Summary of the supervision conducted during the G4 mission, for inclusion in handover documents

Assisting works contractors

G3 Mission

A mission to support the works contractors directly to anticipate geotechnical risks and identify potential discrepancies during drilling / tunnelling works.

Our G3 mission includes:

Before works begin:

verification and analysis of geotechnical data

recommendation of additional soil investigations, if necessary

checking coherence between methodology and ground conditions

During the works:

continuous monitoring of drilling / tunnelling parameters

identification of potential discrepancies and definition of appropriate corrective measures

After the works:

preparation of the works completion report

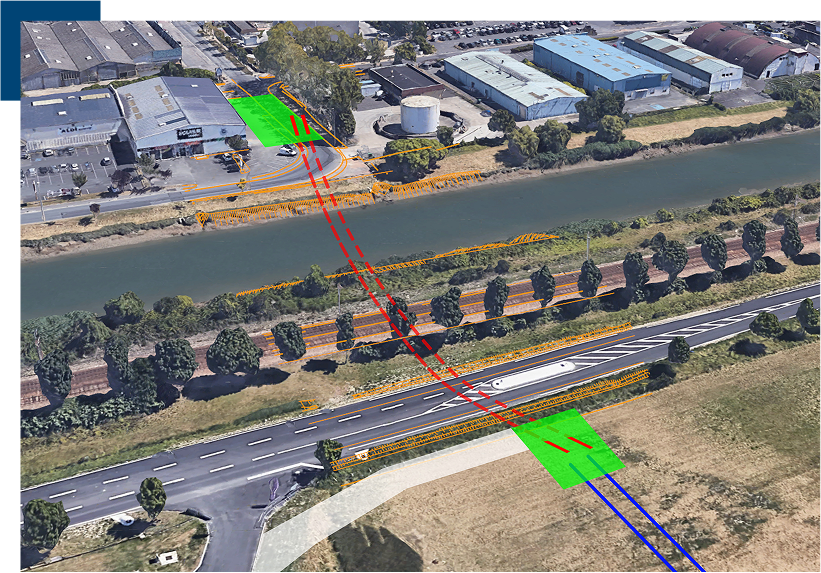

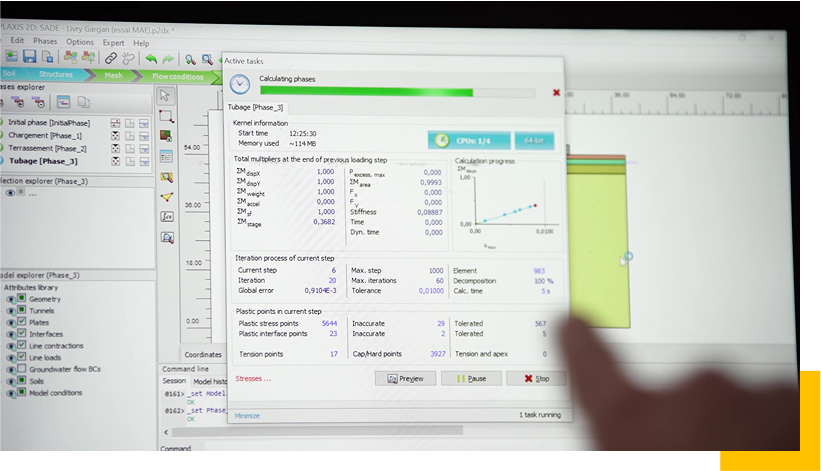

Calculations and modelling

Calculations specific to each trenchless technique which allow for ground behaviour to be modelled so as not to impact the existing infrastructures during the works.

Based on industry and/or proprietary software, our calculations and modelling allow for:

Evaluation of the soil behaviour at each stage of construction

Evaluation of the force required to construct the trenchless structures and to install the final pipes / ducts

Modelling the reaction of soils and existing infrastructures to anticipate the likelihood and severity of identified risks

Designing end structures

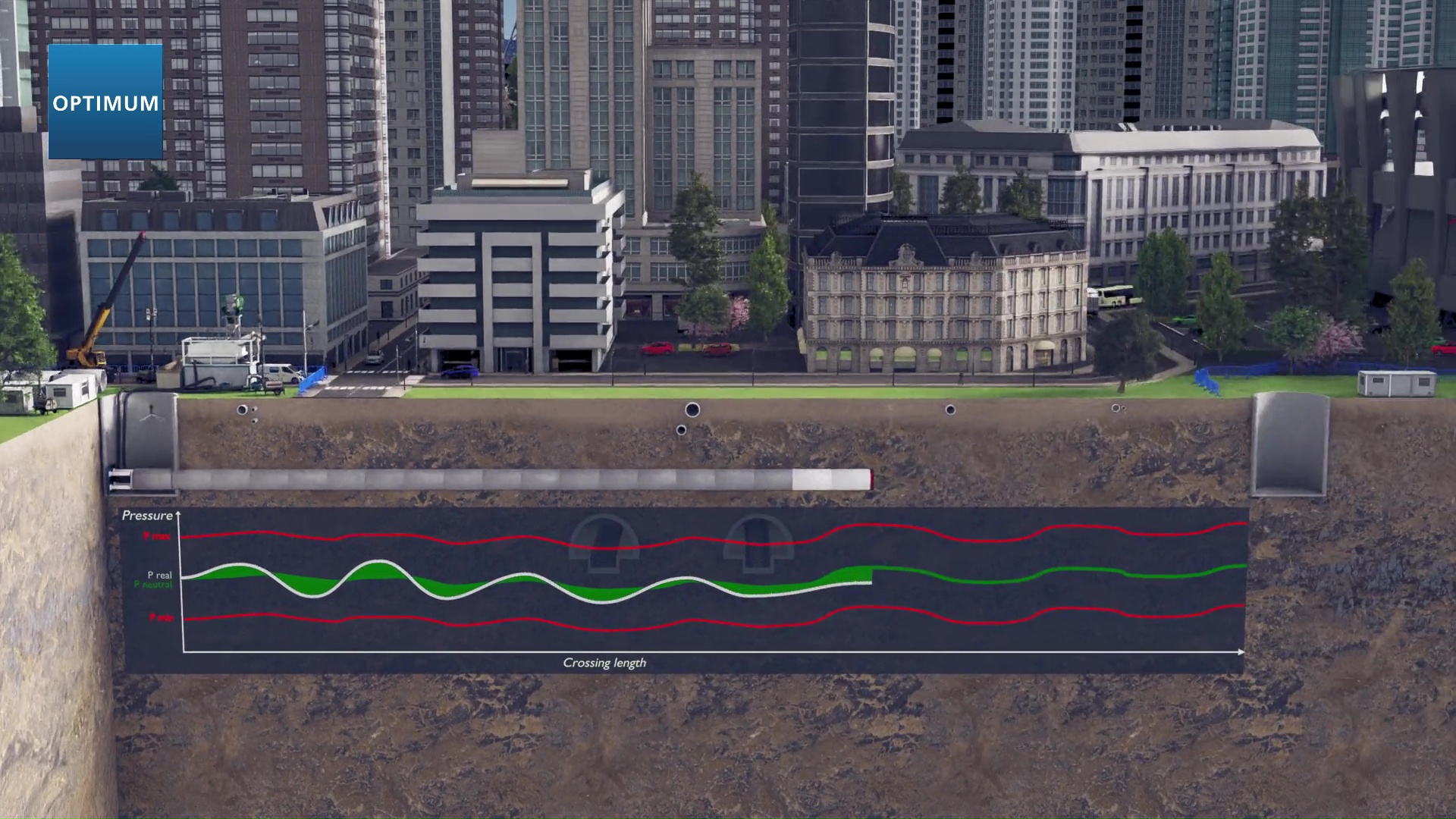

The importance of confinement pressure during microtunnelling operations

Confinement pressures must be continuously

monitored during microtunnelling operations to avoid breakouts and/or settlements

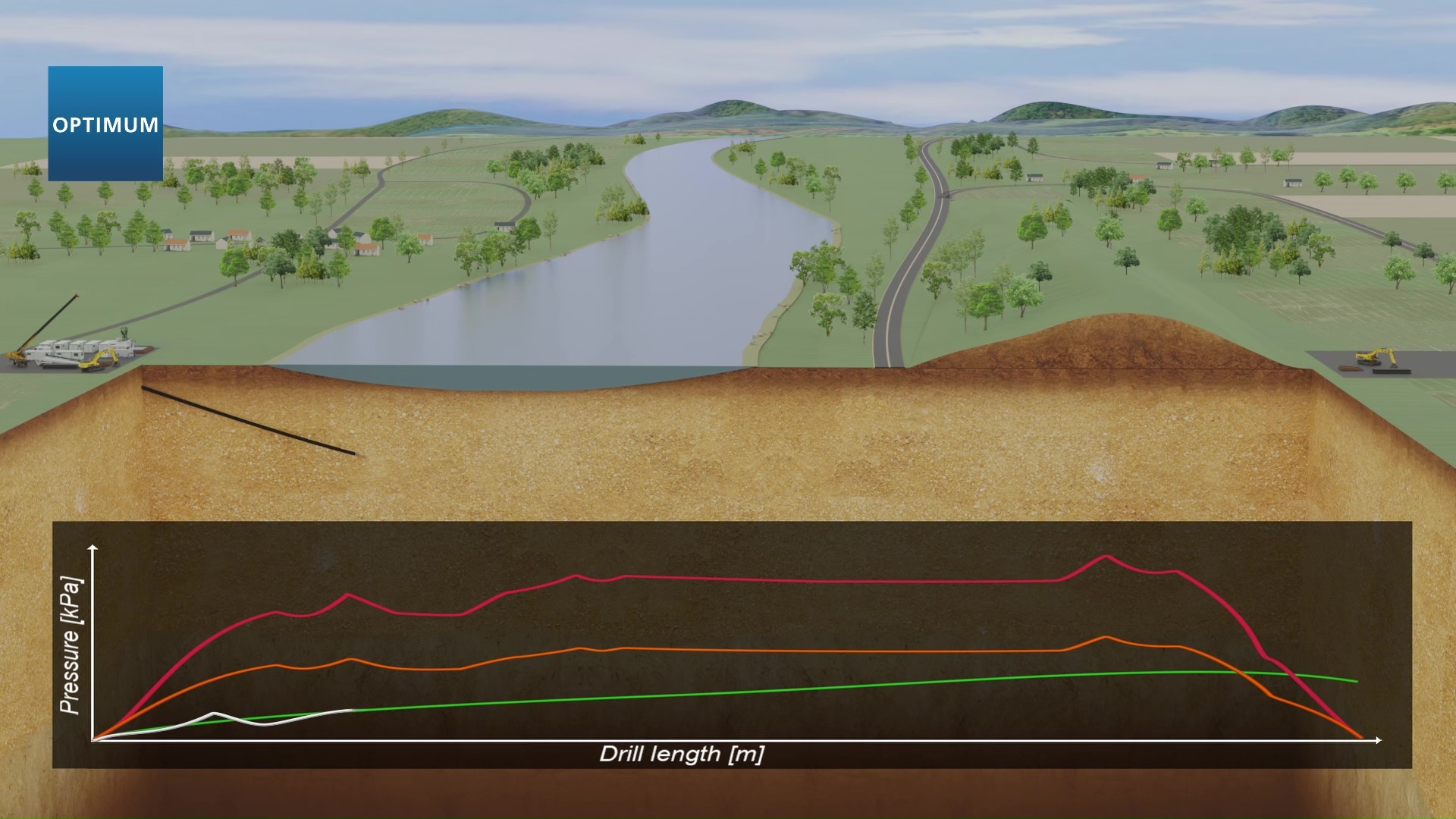

Limiting the risk of breakouts in HDD

Analysing geotechnical conditions allows potential drilling profiles and permissible fluid injection pressures to de determined and evaluated.

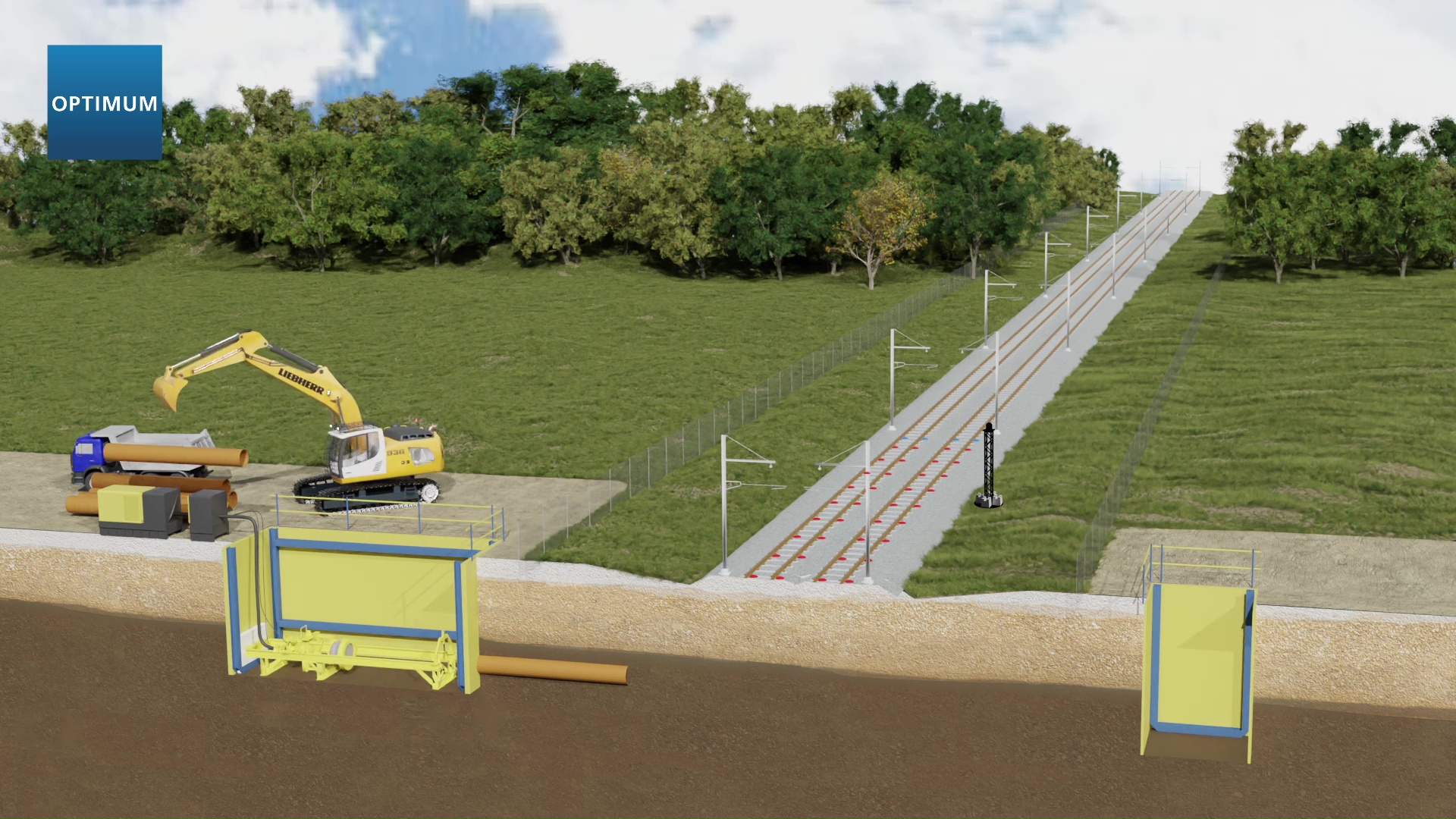

Minimising risks in trenchless crossings under railway lines

Crossing under railway tracks warrants particular attention; geotechnical aspects must be considered right from the design stage.

The importance of geotechnical considerations in Direct Pipe®

Successful Direct Pipe projects require accurate assessment of geotechnical parameters and proper alignment of resources.