Retaining structures

Microtunnelling shafts

Auger boring pits

Traditional tunnels

End structures

To implement certain trenchless techniques, retaining structures at either end may be necessary for the installation of tunnelling equipment and/or the network installation itself.

In these cases, shafts or pits must be designed to allow the works to be carried out in a safe and risk-controlled environment, essential when carrying out deep tunnelling operations.

Microtunnelling shafts and auger boring pits

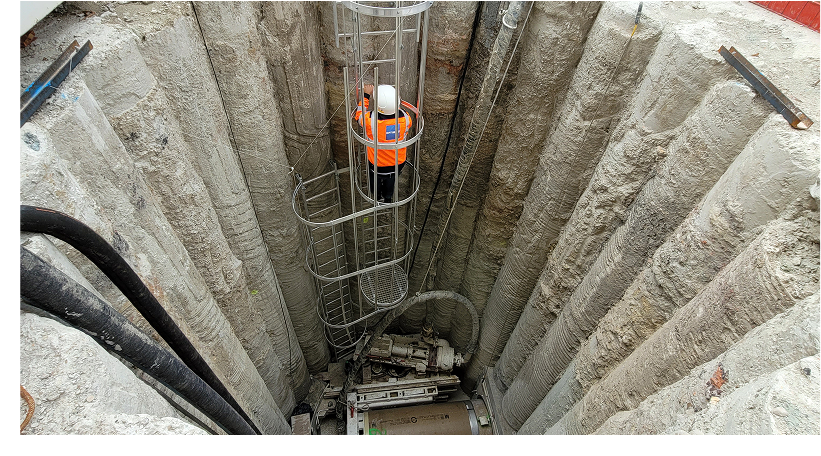

Microtunnelling and auger boring projects generally require shafts (or pits) at both ends. The launch shaft is almost always necessary, and in the vast majority of cases, a reception shaft must also be prepared. These retaining structures must be constructed before tunnelling operations begin to house all the thrust equipment. Once the crossing is completed, the microtunnel or the drill head emerges in the reception shaft (or pit), allowing it to be retrieved.

Depending on the site’s hydrogeological context, the ability to manage water inflow, and the surrounding conditions, one of two shaft (or pit) configurations will be designed.

Waterproof shafts (or pits)

If the tunnelling or drilling work is below the water table with difficult-to-manage water inflows, the construction of waterproof shafts would be more appropriate.

There are three main types of retaining structures for waterproof shafts, all of which allow for work to be carried out in a dry environment below the groundwater table, thus avoiding the need for water pumping.

Shafts (or pits) with sheet piling

Shafts (or pits) with secant piling

Shafts with diaphragm walls

The choice between these three methods is determined not only by the depth of the shaft (or pit), but also by the soil type and the site geology.

Non-waterproof shafts (or pits)

Non-waterproof shafts (or pits) are generally less complex to construct than waterproof ones, their main role being to provide retaining support for the surrounding ground.

While the above-mentioned shaft (or pit) construction methods can also be used, cost implications often lead to the use of other techniques. Again, different methods can be considered, depending on the geotechnical context and surrounding constraints.

Slide rail shafts (or pits)

Timber rib and board shafts (or pits)

Sprayed concrete shafts (or pits)

Associated works

Traditional tunnels

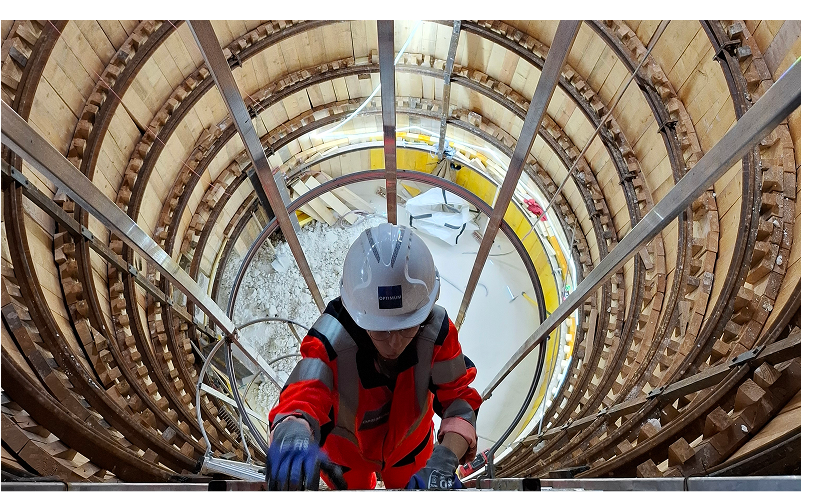

Traditional tunnels are those where the excavation is carried out by operators at the tunnel face, who dig the soil and evacuate it “by hand.” Several methods of ground support are possible, with the two most common being:

Timber-shored tunnels

This type of tunnel can only be implemented when there is no or very little water flow to manage, meaning that excavation is above the water table or in very impermeable soils, such as clay or solid rock.

Metal arches are installed as the tunnel advances, while wooden beams (bastaings) provide support between the arches.

These tunnels do not require a large jobsite area above ground, since no machinery is used either on the surface or in the tunnel. Only ventilation equipment must be installed to allow workers to work in the tunnel.

Typically, these are short tunnel lengths, often carried out in urban areas where the density of existing underground networks prevents the use of mechanized techniques. Moreover, it is possible to deviate the tunnel path according to networks discovered at the tunnel face.

Concrete / Steel pipe shored tunnels

This is a semi-mechanized variation of traditional boring techniques. The manual excavation at the tunnel face is the same as with timber-shored tunnels, but the support is provided by steel or concrete pipes, which are pushed forward as the tunnel advances, using a thrust system installed in the entry shaft.

As a result, the length of these tunnels is limited, since the entire tunnel must advance at once, without the lubrication provided by microtunneling machines.